Molten Synthetic Fuel Oil & Plastic Pallet Generator

(Handling Clean Washed and Sorted Mixed-Waste-Plastic )

The 4R 2-100 F ( Plant-based )

The 4R 2-100 M (Mobile-based)

(Handling Clean Washed and Sorted Mixed-Waste-Plastic )

Implementation Method :

a)Collecting and analyzing data such as the source of plastic waste, the method of sorting, the centralized method, the quantity, the general variety classification, etc.。

b) Setting up the Molten Synthetic Fuel Oil & Plastic Pallet Generation plant based on the amount of plastic waste disposed of daily.

c) Plant Site: Appropriate safe distances from residential areas need to be taken into consideration when planning new plant project. The main plant facility occupies little space but large plant space is needed for plastic storage/shredding /cleaning.

d) Plant Layout Design .

e) Equipment layout, installation and piping, circuits, water supply, civil engineering and other design and planning.

f)To obtain permits from the local authorities and regulatory agencies .

g) Selecting proper equipment / components fabricators for custom –build , bidding and procurement of machinery and equipment and a variety of plant materials .

h) On-site installation and test run of plant equipments and facility 。

i) Plant facility to be handed over to business owners .

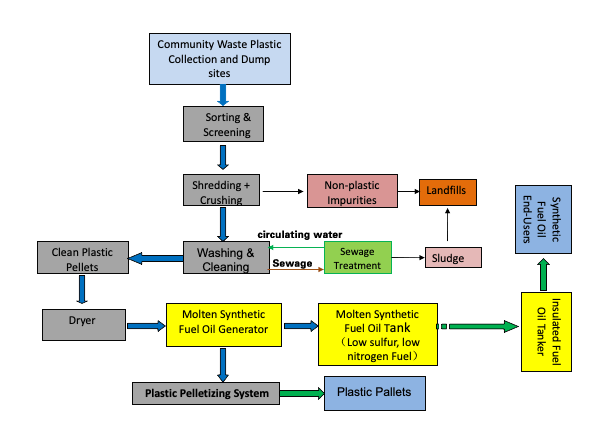

Molten Synthetic Fuel Oil & Plastic Pallet Generation Workflow Flowchart

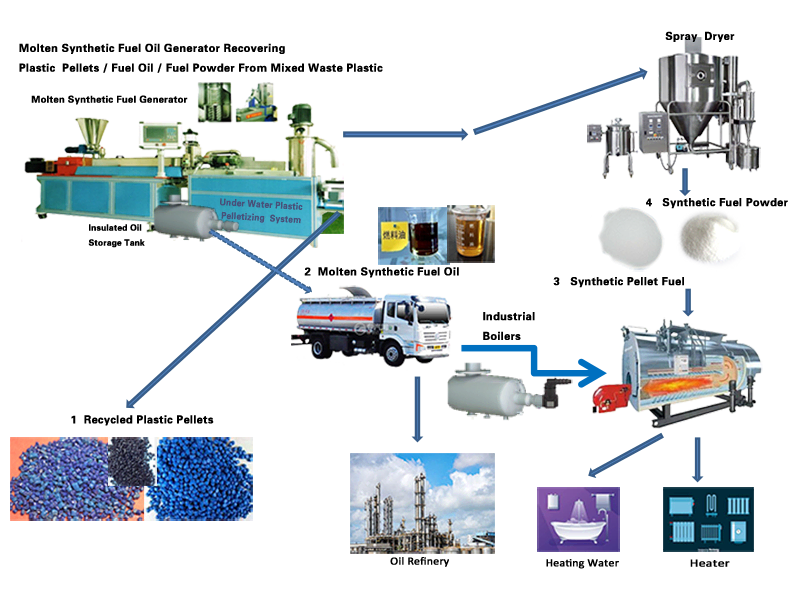

Molten Synthetic Fuel Oil & Plastic Pellet Generator 4R 2-100 Plant-based Schematic Diagram

4R 2-100 P (Plant-based) /M (Mobile-based)

This equipment is a specially designed device designated for mechanical copolymerization. Plastic fragments enter the barrel through the hopper at one end of the barrel, and then are transferred to the other end of the barrel through the screw. In order to have sufficient pressure, the depth of the thread on the screw decreases as the distance to the hopper increases. External heating and internal heat generated by friction between the plastic and the screw cause the plastic to undergo softening, liquefaction, cross-mixing, exchange, and partial copolymerization between various polymer groups, and eventually become a homogeneous composition in the molten state . The composition, or [synthetic fuel oil], is stored in a special insulated tank to keep it in a molten state. Use a special insulated transport vehicle (pre-installed with electric heating equipment), shipped to the user's storage equipment for backup usage.

Molten Synthetic Fuel Oil Generator 4R2-100 F/M is developed using our patented technology “Combined Catalytic Cracking/Catalytic Reforming PTF System” through the simplification of the patented technological process from fourteen chemical production process down to three mechanical copolymerization process . As simplified version of the patented technology above,

The “Mechanical Copolymerization Process “ is simple 、reliable 、user-friendly and very cost-effective solution to meeting various urban administrators’ demands for waste plastic reduction 、recycle 、reuse and renewable management ( Waste Plastic 4R Initiative ) .

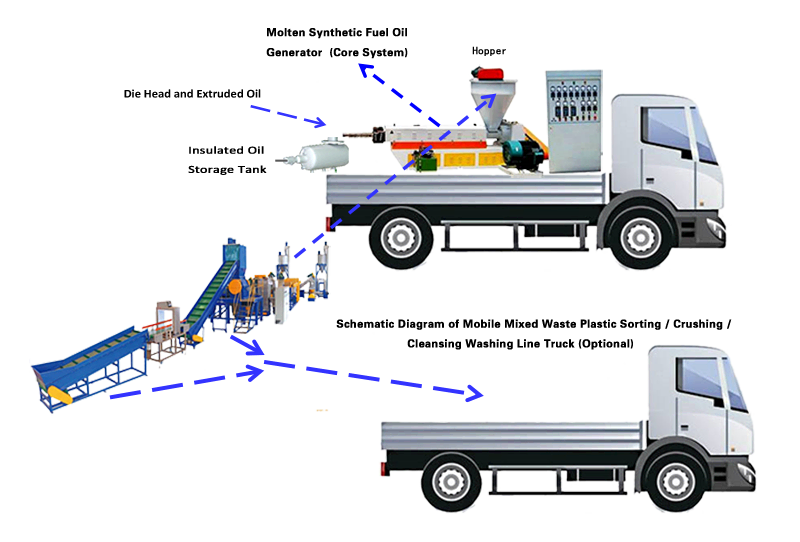

4R 2-100 Mobile(M) Technical Features :

1. The 4R 2-100 M includes two modules, each mounted on a standard 20 / 40-foot container rack

2. All 4R 2-100 M mobile modules are built to meet the needs of standardized shipping container transportation.

4. Plug-and-Run On-site installation service provided by the operation support team

5. Multiple 4R 2-100 M system units can be installed ( multiple units configuration ) to boost waste plastic recycling and disposal capabilities.

6. Rapid deployment across different regions

The following is the basic design diagram of the Molten Synthetic Fuel Oil Generator . It consists of [Molten Synthetic Fuel Oil & Plastic Pallet Generator ] and [Insulation and Transportation System].

Molten Synthetic Fuel Oil & Plastic Pellet Generator 4R 2-100 Mobile Schematic Diagram

Website technical supportwww.app2006.com byjs@app2006.com.